Product list

Crushing Equipment

Sand Making Equipment

Ore Beneficiation Equipment

Drying Equipment

Description

Overview

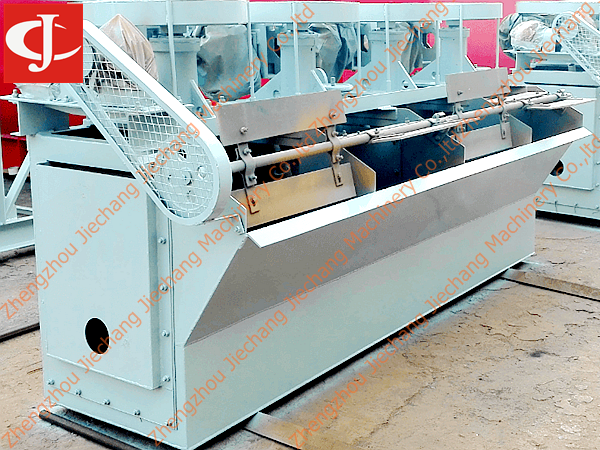

Flotation machine is necessary equipment in most of the ore beneficiation processes, which can be used to separate copper, zinc, lead and other nonferrous metal and non-metal minerals. So, it is also called copper ore flotation machine according to the materials to be processed.

The flotation machine can form a flotation separation loop by itself without any auxiliary equipment and it is allocated horizontally, which favors the change of flow. It is the key equipment in ore beneficiation production line.

Principle

Flotation cell is also being called flotation separator, flotation machine and flotation-cell.

The working principle of flotation cell: The mineral pulp being added pharmacy will be passed into the gas, and the electric rotor will bring the movement of part pieces to mix and stir in order to make the mineral and gas be sufficiently mixed, and at this minute, the grain of mineral pulp is above on the bubble, floating on the surface, which can reach the purpose of sorting the mineral material through blade scrapings.

Feature

1.High separation precision, large air-absorption capacity.

2. High processing capacity, unit volume capacity is 2-3 times of conventional ones.

3. The operation cost is low, saving power by 1/3 to 1/2.

4. Reasonable circulation of mineral slurry.

5. Simple operation, high degree of automation.

Product Model

Hot-selling Products