Product list

Crushing Equipment

Sand Making Equipment

Ore Beneficiation Equipment

Drying Equipment

Description

Overview

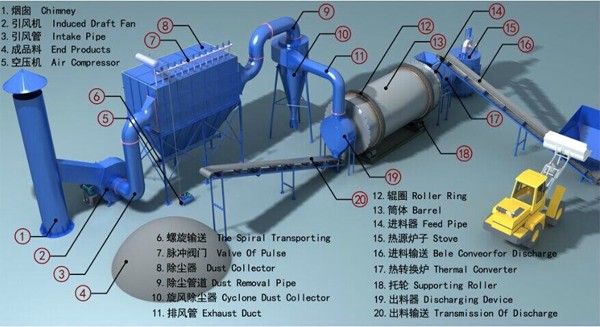

Three-drum dryer is a contact internal heating conduct dewatering unit. During dewatering process, heat is transmitted from the inner wall of the roller to the external wall, passes through the food materials on the external wall, and then vaporizes the moisture of the materials. It is a continuous drying machine.

Three-drum dryer is used to dry particle materials with certain humidity like yellow sand used in the dry powder and mortar industry, and many kinds of sands used in the casting industry.

Principle

Materials enter the inner side of the drum through the feeding device to realize current flow drying process, and then the materials enter the middle layer of the inner wall through the other end to realize counter current drying process. They are lifted in over and over in the middle layer which advance in two-steps forward and one-step back way. The three-drum dryers absorb heat from both inner drum and middle drum, which extend the drying time and realize the best drying condition. Finally, materials fall into the external layer of the drum from the other end of the middle layer, processing in a rectangle multi-loop way. The dried materials move quickly out of the drum under the hot air, while the wet ones remain because of their own weight. Materials are dried completely inside the rectangle shoveling plate and then cooled by the single drum cooler, thus finishing the whole drying process.

Feature

Three-drum dryer has compact structure and covers a small area which is half of the single drum dryer does. The three-drum dryer works reliably with low energy consumption and high heat efficiency which realizes good material drying effect, simple automation control and few operating staff.

Product Model

Hot-selling Products