Product list

Crushing Equipment

Sand Making Equipment

Ore Beneficiation Equipment

Drying Equipment

Description

Overview

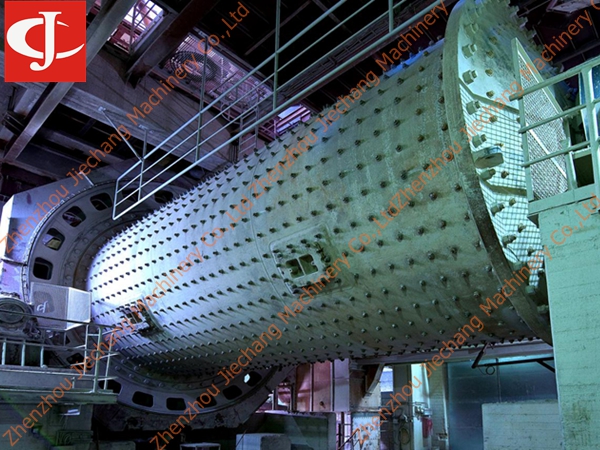

Raw material mill is the key equipment that smashes materials which have already been broken by crushers and been mixed. The raw material mill as a type of ore grinder is mainly used by cement plant to crush and grind power materials, and it also plays an important role in the industries of metallurgy, chemical engineering and electricity for the grinding process of all kinds of ores and other materials. In addition, like the slag mill, the raw materials mills are suitable for the open flow grinding process cooperating. Together with the power concentrator, they form the circulating ring flow grinding system. There are two main grinding mils: dry type raw material mill and the wet type one.

Principle

The raw material mill or slag mill adopts the edge transmission model. After materials are transported into the ore grinder continuously via the feeder, the motor drives the mill cylinder to rotate through the reducer. Materials are conveyed to the first cabin in a spiral way along the hollow shaft and the steel balls and the materials inside the mill are turned over by the cylinder in the effect of friction and centrifugal force. When materials are lifted to certain height, they are scattered down like a material curtain and then are impacted by the steel balls. The qualified crushed products are discharged out of the raw material mill and are separated by the separation equipment. The unqualified materials in the circulating system will return to the mill for further impacting and grinding processes until reaching the required fineness.

Feature

1. The advanced and unique streamlined design can reduce the ventilation resistance, and expand the effective volume.

2. Various liner structures can improve the grinding efficiency.

3. Negative pressure in the working process can avoid the phenomenon of powder leaking.

4. The material drying degree can reach 6%-8% because of heat preserving method adopted.

Product Model

Hot-selling Products